In the midst of a growing environmental crisis, novel recycling methods are emerging as vital tools to create a eco-friendly world. A system that can convert plastic waste into reuseable forms, and reintegrating it into the manufacturing process are some of the most important advancements. The techniques, which range from shredding to granulating to pelleting, are changing the way that industries deal with waste. Jian Kwang Machine Industrial is in the forefront of this shift, with its state-of-the technology that enables companies to maximize their material utilization while decreasing the environmental impact.

Plastic Shredder Machines – The Foundation

The journey from plastic waste to reusable material begins by using a plastic shredder. These machines are robust and are designed to break down plastic waste from industrial scraps to packaging for consumer use into manageable pieces. The recycling shredder machine, for example, uses advanced blade configurations as well as high-torque motors and other features to cut even tough materials such as PET bottles or PVC pipe.

Image credit: jkm3r.com

Shredding is a crucial first step because it prepares plastic waste to be further processed. Shredders increase the efficiency of downstream machines by reducing their size and volume. They also decrease the use of energy and wear. Jian Kwang shredders have earned the trust of clients from diverse regions like the Middle East and Africa. They are capable of handling high-throughput processes, making them essential for large-scale facilities trying to meet the environmental standards.

Granulation – Refining plastic for reuse

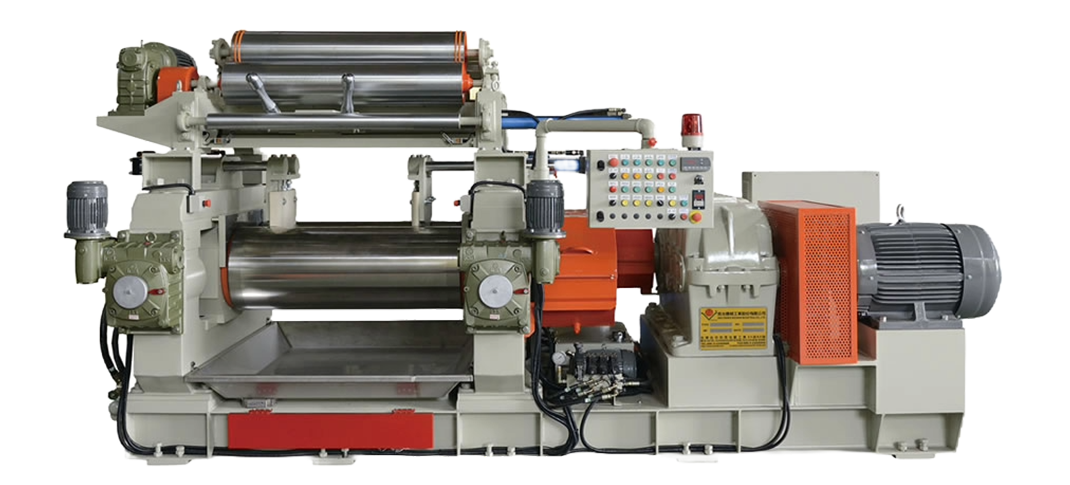

The plastic fragments that have been shredded require some further refinement before being able to be used to manufacture. Plastic recycling granulator machine take these fragments and convert them into uniform granules that are easier to melt, mold, and transform into new products. Jian Kwang advanced systems are equipped with high-speed mixing and dispersion mixers. They ensure that each batch of granules is produced in accordance with strict requirements for dimensions, purity and density.

The process of granulation is vital to maintain the quality of the material. Contaminants like residue or inconsistencies in particle size can affect the performance of recycled materials. Jian Kwang’s complete plant system, which integrates crushers, granulators as well as extruders provides an efficient workflow that maximizes output. Global manufacturers have adopted these processes, such as Crocs Inc. which is based on recycled granules for longevity and sustainability.

Pelletizing is the building blocks of recycling

The pinnacle of the recycling process is the plastic pelletizing equipment which converts granulated plastic into uniform pellets which serve as raw material for new products. Pelletizers melt the granules before they extrude them through a die which is then cut into pellets using advanced techniques like strand-cutting or water-ring technology. Jian Kwang pelletizing machines are well-known for their precision. They make pellets of uniform size and shape, which are vital for industries such as packaging, automotive and consumer goods.

Pelletization isn’t an isolated technical process, it’s the cornerstone of a circular economy. The machines eliminate the need for virgin plastics by creating quality, long-lasting pellets. This reduces costs and environmental impacts. Jian Kwang’s innovative designs, such as their water-ring-cutting kneader extruding plants can improve the quality of pellets while reducing the waste. Their machines are a popular option for South America and USA where environmental rules are becoming more stringent.

Vision for a Sustainable Future

Jian Kwang Machine Industrial stands apart not only for its equipment, but also because of its dedication to sustainability as well as the satisfaction of its clients. The red sun in Taiwan, as well as Ali Mountain’s blue, reflect values of trust, continuity and cooperation. This is the basis of their strong R&D concentration, which ensures that every plastic shredder, recycling shredder, and pelletizing machine from plastic delivers unparalleled performance.

Jian Kwang also offers comprehensive services, from timely maintenance, to turnkey customized solutions such as stationary-use two-color plate plants. They have the ability to cater to a wide range of clients such as small recycling companies to big industry players like Crocs. Jian Kwang empowers companies to achieve their environmental goals, while still maintaining profitability.

The development of a circular economic system

The plastic recycling granulator machine shredder, plastic pelletizing machine are more than industrial equipments, they are the enablers of a sustainable and greener environment. These technologies help reduce landfill waste, protect natural resources, and encourage sustainable production by turning plastic waste to valuable pellets. Jian Kwang is a recycling expert who can help the industry tackle the current challenges while creating the future that is more sustainable.