In the world of advanced manufacturing, where precision and dependability are not a matter of debate, the spindle stands as one of the most important parts of any machining process. The spindle is accountable for precision, speed and consistency, no matter if you are carving high-grade aerospace alloys or fine-tuning components that require extremely tight tolerances.

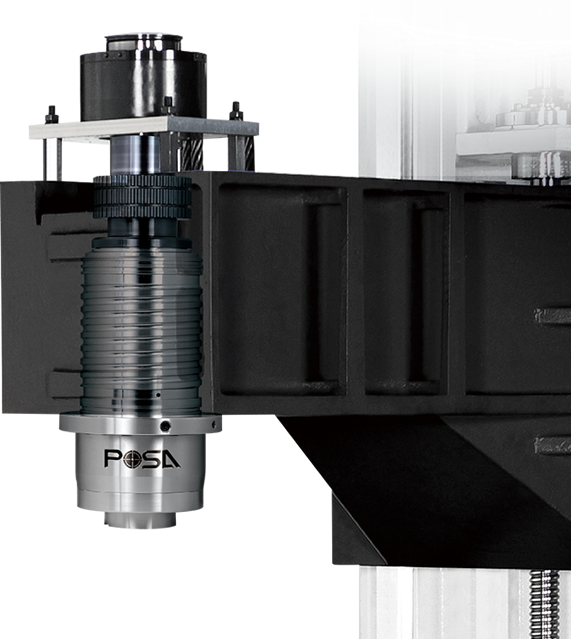

Spindle manufacturers with a high-end reputation like POSA are leading this niche industry, changing the quality and endurance of industrial machining environments.

The reason the Spindle Is the Heart of the Machine

The spindle is the main component of all CNC machines. Imagine the spindle is the center of a CNC lathe or machining centre. It is the engine that drives the cutting tool at high accuracy, stability and torque. An unbalanced or poorly designed spindle isn’t only the result of defective parts, it could also damage the machine, shorten tool life, and throw off the entire production cycle.

Image credit: posa-spindle.com

Precision spindle technology could make all the difference. In contrast to standard components that are mass-produced and assembled on the fly, precision spindles are meticulously designed, tested and calibrated to function under intense conditions and high demands.

POSA Machine More than a Spindle Maker

While many spindle companies claim to provide high-quality products however, very few can boast the depth of experience and engineering knowledge that POSA Machinery has accumulated over decades. It is known for its rigorous in-house testing protocols and commitment to international quality standards, POSA does more than just manufacture spindles, they create solutions designed to meet the needs of a variety of modern-day industries.

From high-speed micro-machining systems to a heavy-duty material removal system Spindles from POSA can be found in everything from grinding machines for tools to vertical and horizontal machines. Each spindle is supported by an extensive R&D process that focuses not only on performance, but on long-term reliability, vibration control, and thermal stability.

The Evolution of the CNC Lathe Spindle

In recent times, the CNC lathe spindle’s advancement has been quite remarkable. These days, spindles are not just a spinning shaft. They integrate sensors and cooling systems, and also a smart balancing mechanism. POSA’s CNC lathe spindles are an excellent example of how they combine high-speed capabilities and exceptional torque and rigidity that allow machinists to handle both fragile materials and hard metals while maintaining quality. Incorporating advanced ceramic bearings and top-quality steel construction, these spindles limit thermal expansion and maintain the tight tolerances during long runs. This is directly translated into higher quality parts and reduced downtime.

Customized Machining Spindles that Meet the demands of the real world

There’s no such thing as a one-size-fits-all machining spindle especially in industries like aerospace, automotive, and die – and mold manufacturing. POSA is aware that each industry requires its own unique requirements, be it for spindle speed and load capacity or environmental resistance. They offer custom spindle configurations in accordance with the particular requirements of each customer. When it comes to designing a spindle for vertical milling operations or the integration of a high-frequency spindle in a compact unit, POSA provides the flexibility and engineering assistance that modern-day manufacturers require.

More than Machines: A Dedication to Craftsmanship

The philosophy behind POSA’s spindles is what separates it from other spindles. The POSA philosophy is a blend of skill and ingenuity. Their engineers listen to their customers’ needs and adjust their products to meet evolving demands of the market. If machine uptime and reliability are key factors in a production line’s success choosing the most suitable spindle partners is critical.

Final Thoughts

The future of manufacturing is not solely about more efficient machines, but also more intelligent and more reliable parts. POSA Machinery is an excellent illustration of the outcomes that can be achieved by spindle manufacturers who combine technical expertise with a concentration on customer service. Whether you need a high-performance CNC lathe spindle, a heavy-duty machining spindle, or a finely tuned precision spindle, choosing the right spindle isn’t just a detail it’s a decision that shapes everything downstream.